Бид олон жилийн туршлагатай, чадварлаг, найдвартай түншүүдтэйгээ хамтран Монгол дахь бүс нутгийн харилцагч нартаа дэлхийн шинэ шинэлэг шийдлүүдийг үргэлж хүргэсээр байх болно.

Бүтээгдэхүүн

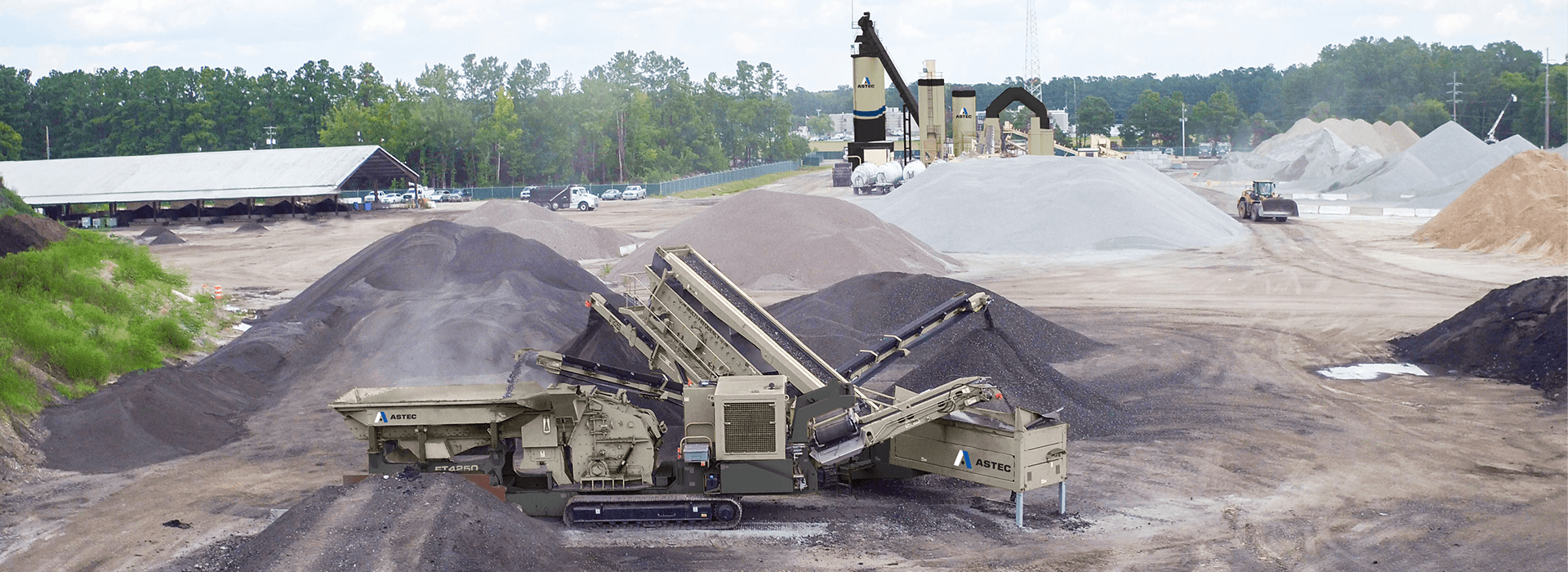

Таньд Уул уурхай, Зам, Барилга дэд бүтцийн салбарын тоног төхөөрөмж, үйлдвэр хэрэгтэй юу? Бидэнтэй шууд холбогдож өөрт хэрэгтэй мэдээллээ аваарай.

Ханган нийлүүлэлт

Манай компани нь дараах салбаруудын үйлдвэр, тоног төхөөрөмж, сэлбэг хэрэгслүүдийг үйлчлүүлэгчийн хэрэгцээ шаардлагад нийцүүлэн найдвартай, түргэн шуурхай ханган нийлүүлж байна.

• Уул уурхай, ашигт малтмал

• Зам

• Барилга дэд бүтэц

Бид Америкийн Нэгдсэн Улс, Канад, Өмнөд Африк, Швед улсын нэр хүнд бүхий үйлдвэрлэгч, компаниудыг Монгол Улсад албан ёсны төлөөлөгчөөр ажиллаж байна.

Угсралт, Ашиглалт

Бид таны худалдан авсан үйлдвэр, тоног төхөөрөмжийн угсралт суурилуулалт, тохиргоо, сургалт, засвар үйлчилгээг бүрэн хариуцан ажиллаж байна.

Зөвлөх үйлчилгээ

Уул уурхай, ашигт малтмал, зам, барилга дэд бүтцийн салбаруудын баяжуулах, боловсруулах, үйлдвэрийн төсөлд шаардлагатай бүх төрлийн ажлуудад бид харилцагч нартаа мэргэжлийн зөвлөгөө өгч ажилладаг.

• Технологийн судалгаа

• Технологи схем, инженеринг, зураг төсөл

• Техник, технологи, тоног төхөөрөмжийн сонголт

• Тоног төхөөрөмжийн угсралт, ашиглалт, сургалт

Дэвшилтэт техник технологийг санал болгох, үйл ажиллагааг сайжруулах.

Борлуулалтын дараах үйлчилгээ

Харилцагчийн үйлдвэр, тоног төхөөрөмжийн найдвартай байдлыг ханган ажиллахын тулд мэргэшсэн инженер чадварлаг баг бүрэлдэхүүнээр оношилгоо, ашиглалтын зөвлөмж, баталгаат засвар үйлчилгээг хурдан шуурхай, чанарын өндөр түвшинд хийж гүйцэтгэдэг.

Мэдээ мэдээлэл

Авто зам - 2022 Олон улсын үзэсгэлэн