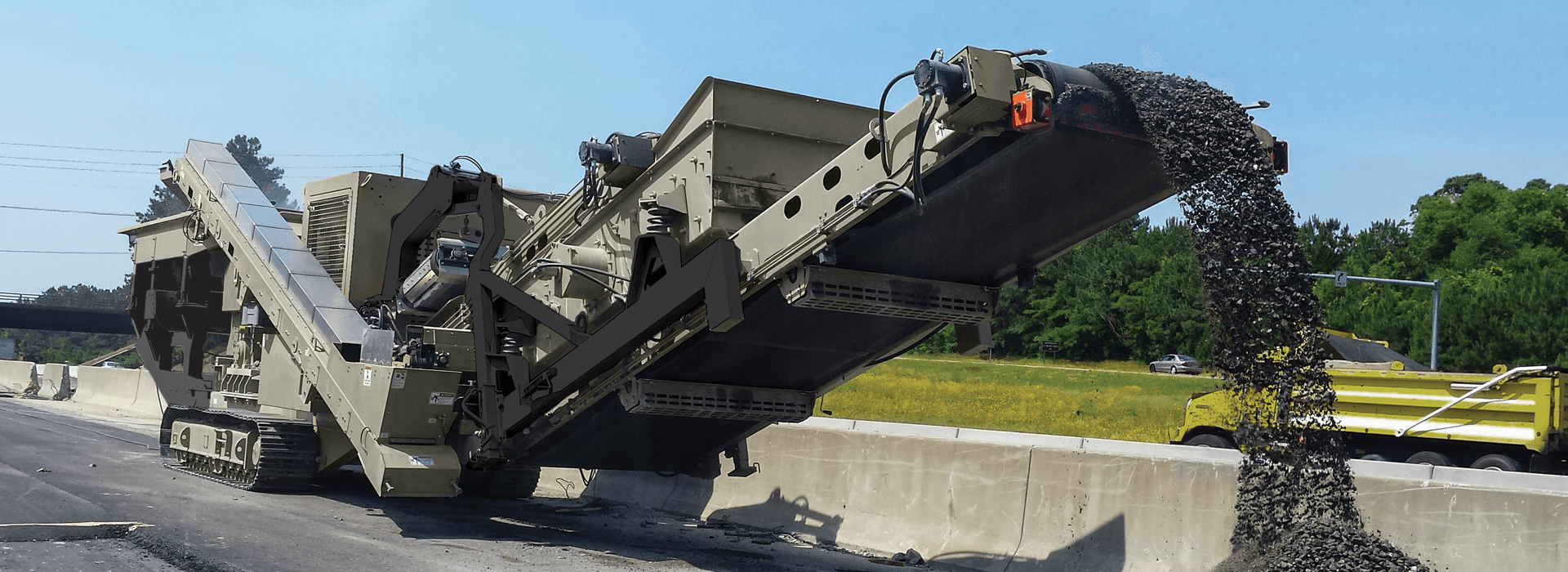

CRUSHING - БУТЛУУР

Astec designs and manufactures a wide range of quality crushing equipment that is technology-driven and durably-designed for modern crushing operations

Our state-of-the-art machinery is specifically built to accommodate a variety of applications and materials with high productivity and profitability. Our innovative line of jaw crushers, cone crushers, impactors and coal processing equipment offers producers a line of reliable products for their operational needs

JAW CRUSHERS - Хацарт бутлуур

HYDRA-JAW® CRUSHERS - HYDRA Хацарт бутлуур(гидро тохируулгатай)

• Chamber clearing system allows jaw to be started in as little as 15 minutes

• Hydraulic adjustment reduces downtime

• Toggle tensioning system eliminates the need to adjust springs when changing settings

IRON GIANT JAW CRUSHERS - Iron jiant Хацарт бутлуур

• Alloy steel plates made of AR400 alloy steel for long service life

• Standard heavy-duty jaw dies

• Fast, safe and reliable hydraulic wedge lock adjusting system

PIONEER® JAW CRUSHERS - Pioneer Хацарт бутлуур

• 25% more capacity than cometitive units

• Quick closed-side setting adjustment for enhanced safety

• Class-leading stroke offers greater throughput

CONE CRUSHERS - Конусан бутлуур

TITAN™ CONE CRUSHERS - TITAN™ Конусан бутлуур

• Sizes randing from 200-500 horsepower

• Patented hybrid thrust bearing allows for crushing at tighter settings

• Patented anti-spin system prevents head spin to extend manganese life

KODIAK® CONE CRUSHERS - KODIAK® Конусан бутлуур

• Sizes ranging from 200-500 horsepower

• Tramp iron relief system minimizes the amount of damaging backpressure buildup

• The patented liner retention system simplifies liner changes

IMPACTORS - Цохилтот алхан бутлуур

HYBRID HORIZONTAL SHAFT IMPACTORS - Хосолсон хэвтээ голт цохилтот бутлуур

• Large expansion chamber for increased production with less horsepower

• Designed for durability

• Removable blow bars provide greater ease-of use

VERTICAL SHAFT IMPACTORS - Босоо голт цохилтот бутлуур

• Capacities from 75-500 STPH

• Externally-adjustable feed tube for reduced maintenance

• Hydra-arm assembly lifts the crusher lid for 360° for easy maintenance

HORIZONTAL SHAFT IMPACTORS - Хэвтээ голт цохилтот бутлуур

• Capacities from 100-450 STPH

• Replacement blow bars and bolt-on apron liners for extended wear life

• High-performance rotor is similar to a solid rotor with the accessibility of segmented rotor