SCREENING - ШИГШҮҮР

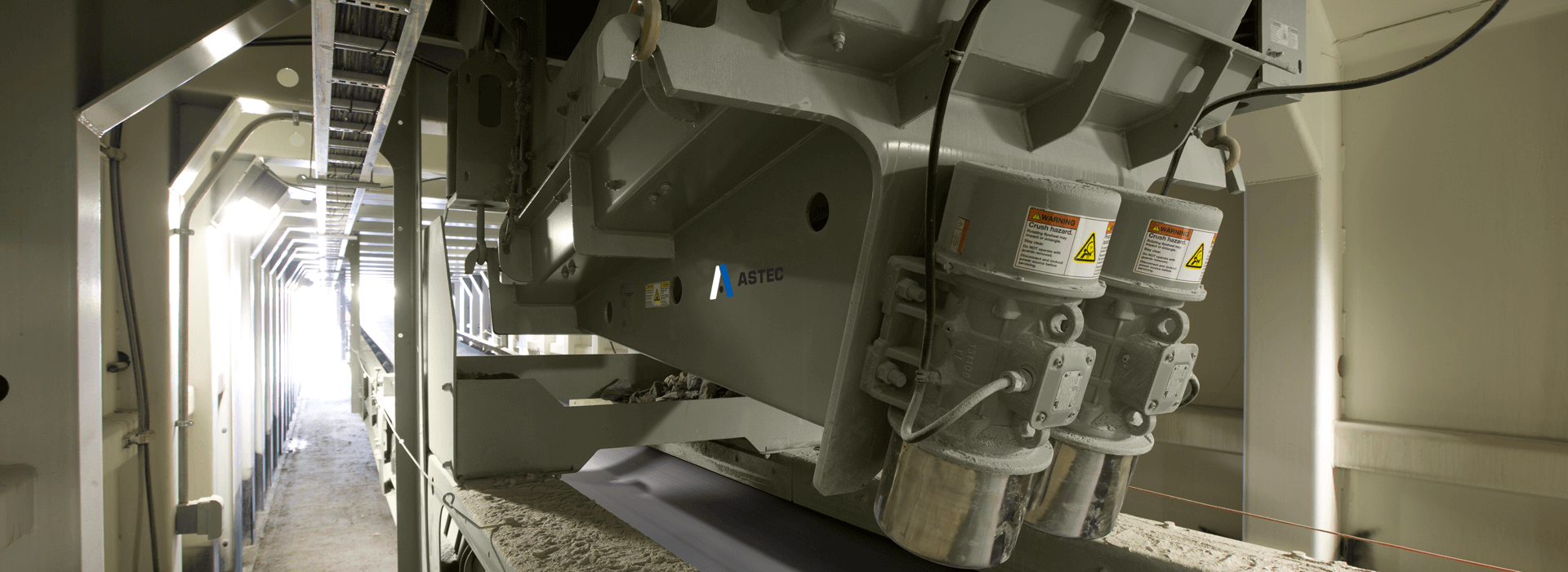

Designed to operate in a variety of applications, including heavy-duty aggregate, concrete, asphalt and recycling, Astec designs and manufactures versatile and efficient screening, feeding and sorting equipment.

Our state-of-the-art machinery is specifically built to accommodate a variety of applications and materials with high productivity and profitability. Our innovative line of jaw crushers, cone crushers, impactors and coal processing equipment offers producers a line of reliable products for their operational needs

HIGH FREQUENCY SCREENS - Өндөр давтамжит шигшүүр

High Frequency Screens

• Driven by variable-speed hydraulic vibrators

• Designed with unique rotary tensioning

system

• Hydraulic screen angle adjustment makes

changes quick and easy

COMBO SCREENS - Комбо шигшүүр

Combo Screens

• A sloped feed zone accelerates

material, offering thinner bed depth for

quicker fines separation

• Offers the benefits of a triple-shaft vibrating

mechanism

• Quick and easy screen media changes

compared to conventional designs

DEWATERING SCREENS - Усалгаат шигшүүр

Dewatering Screens

• Dewater sand products to a level typically not

possible with fine material washers

• Available in sizes ranging from 2'x 7 to 8'x 16

with processing rates up to 400 STPH

• Bolt-in UHMW pan side liners protect pan sides

from premature wear

INCLINE SCREENS - Налуу шигшүүр

Grizzly Scalping Screens - GRIZZLY SCALPING шигшүүр

• TL vibrator mechanism

• Single-and dual-shaft models available

• Deep grizly sections

Valu-King° Incline Screen - VALU-KING® налуу шигшүүр

• Offered in sizes from 4x 8 single deck up to 6

x 16' triple deck

• A snap-in, urethane labyrinth seal keeps dust

out and eliminates the downtime and cost

• Deck frames are designed for performance and

endurance

Vibro-King TL° Incline Screens - VIBRO-KING TL® налуу шигшүүр

• Offers single, double, triple and four deck

models ranging from 5'x 14' to 8'x 24'in screen

size

• Designed for heavy-duty scalping of coarse

stone, fine sizing, and wet or dry processing

• Incorporates spherical roller bearings and

open tube, flow through oil lubrication

HORIZONTAL SCREENS - Хэвтээ шигшүүр

Oval Stroke Horizontal Screens

• Convenient low screen height

• Triple-shaft design

• Variety of configurations available

FEEDERS - Тэжээгүүр

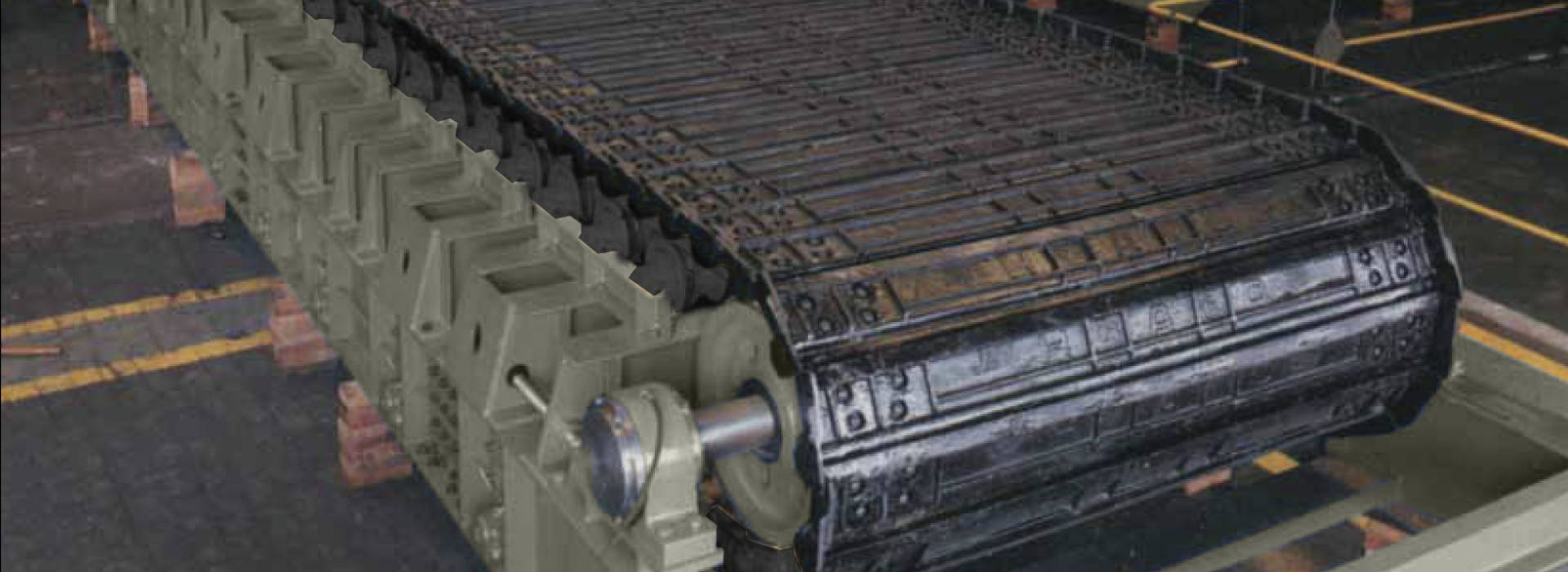

Apron Feeders - Хормогч тэжээгүүр

• Accurately control the feed rate to prevent

surge loads

• Rugged, heavy-duty construction and are

designed to handle feed sizes of up to 60"

(1,500 mm)

• Built to withstand wet, sticky or clay-like

material

Vibrating Grizzly Feeders - Чичиргээт хуруун тэжээгүүр

• Adjustable gear timing

• Bolt-on counterweights for maximum stroke

adjustment

• Double-row spherical bearings

Pan Feeders - Хавтант тэжээгүүр

• Mechanically driven with re-

greaseable bearings

• Built with bolt-in replaceable liners

• Heavy-duty formed deck