WASHING & CLASSIFYING - Угаагч & Ангилагч

Astec produces a variety of washing and classifying equipment suited for a wide range of applications and production goals.

Our expertly engineered components and plants help producers meet the most stringent material specifications and get the most out of their material. With complete lines of scrubbing, sand classifying, dewatering, water clarification and other plants and systems, Astec has washing and classifying equipment for any operation.

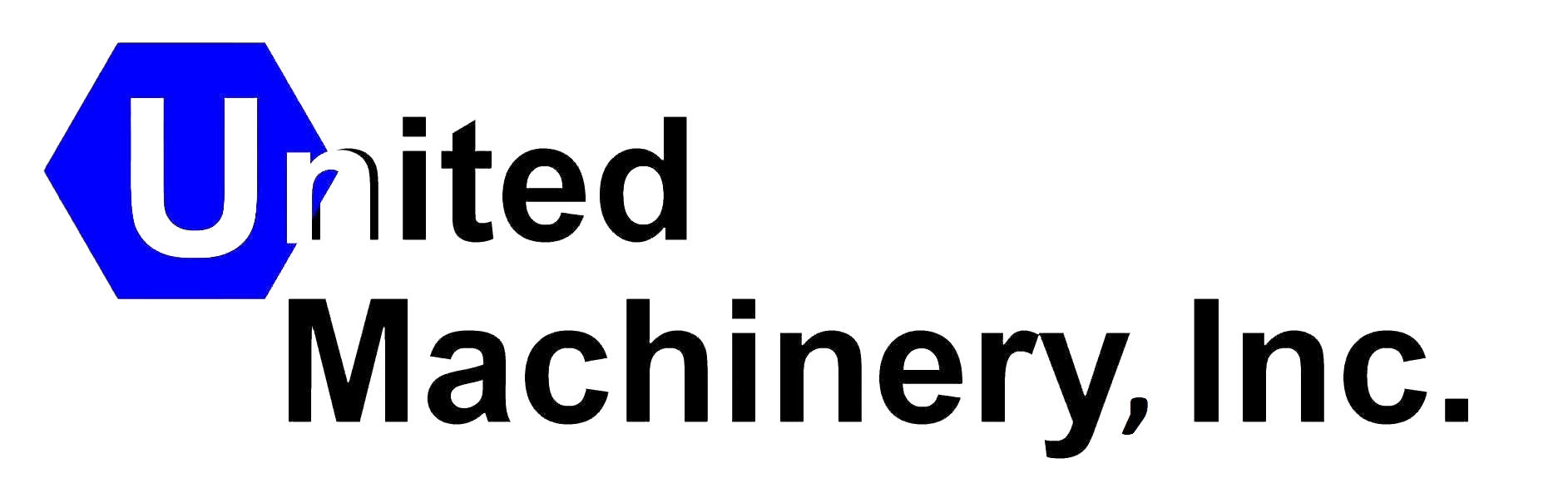

SCRUBBING EQUIPMENT - Угаах төхөөрөмж

Blademills - Ирт тээрмэн угаагч

• Cast Ni-hard two-piece paddle tips with a

corrugated face increase scrubbing and wear

life

• The feed box ensures material is slurried before

entering the unit for maximum scrubbing

• Large clean-out ports ensure ease of

maintenance and reduce operating costs

Coarse Material Washers - Том материал угаагч

• Offers a throughput of 500 STPH for increased

productivity

• Highly efficient and reliable drive assembly

reduces horsepower requirements

• Large clean-out ports ensure ease of

maintenance and reduce operating costs

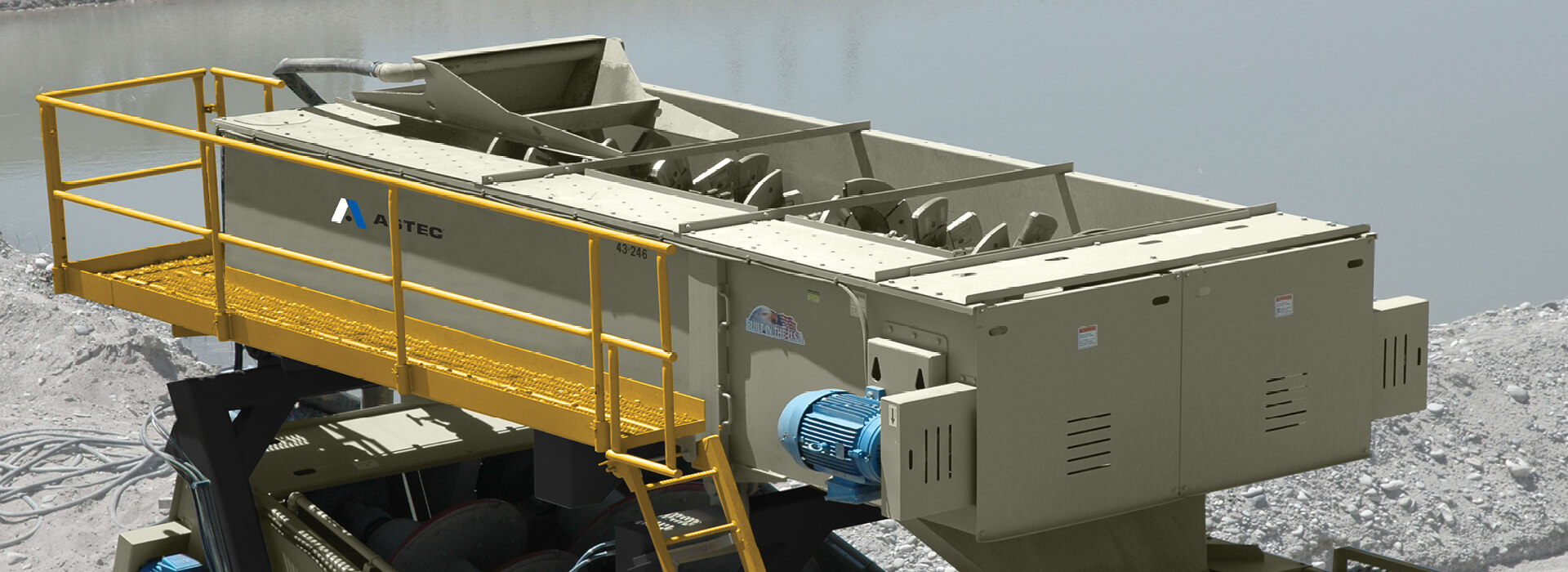

Log Washers - 2 голт угаагч

• The reverse involution design offers more

scrubbing actions

• The heavy-duty, steel plate construction

provides years of leak-free operation

• Large clean-out ports ensure ease of

maintenance and reduce operating costs

SAND CLASSIFYING EQUIPMENT - Элс ангилах тоног төхөөрөмж

Dewatering Cyclones

• Eficient and effective dewatering

• Feed stream effortlessly blends with rotating

slurry inside the chamber

Classifying cyclones

• Efficient and effective classifying

• Unique geometry and design

Classifying Tanks

• Available in sizes from 8'x 32' up to 12'x 48

• Self-supporting tank allows for flexibility when

equipment is under the classifying tank

• Standard self-aligning urethane dart valves

and standard snap-in urethane valve seats

Fine Material Washers

• The lowhorsepower requirement reduces

operating costs while increasing throughput

• Features standard, high-efficiency reducers

and bearings

• Adjustable overflow weir boards and collecting

flume allow control of the overflow slurry

WASHING PLANTS - Угаах үйлдвэр

Portable Sand Classifying Plants - Зөөврийн элс ангилах үйлдвэр

• Plants are equipped with a classifying tank and

dewatering screw

• Ability to produce two specific products and a

non-specific byproduct

• Low-profile design

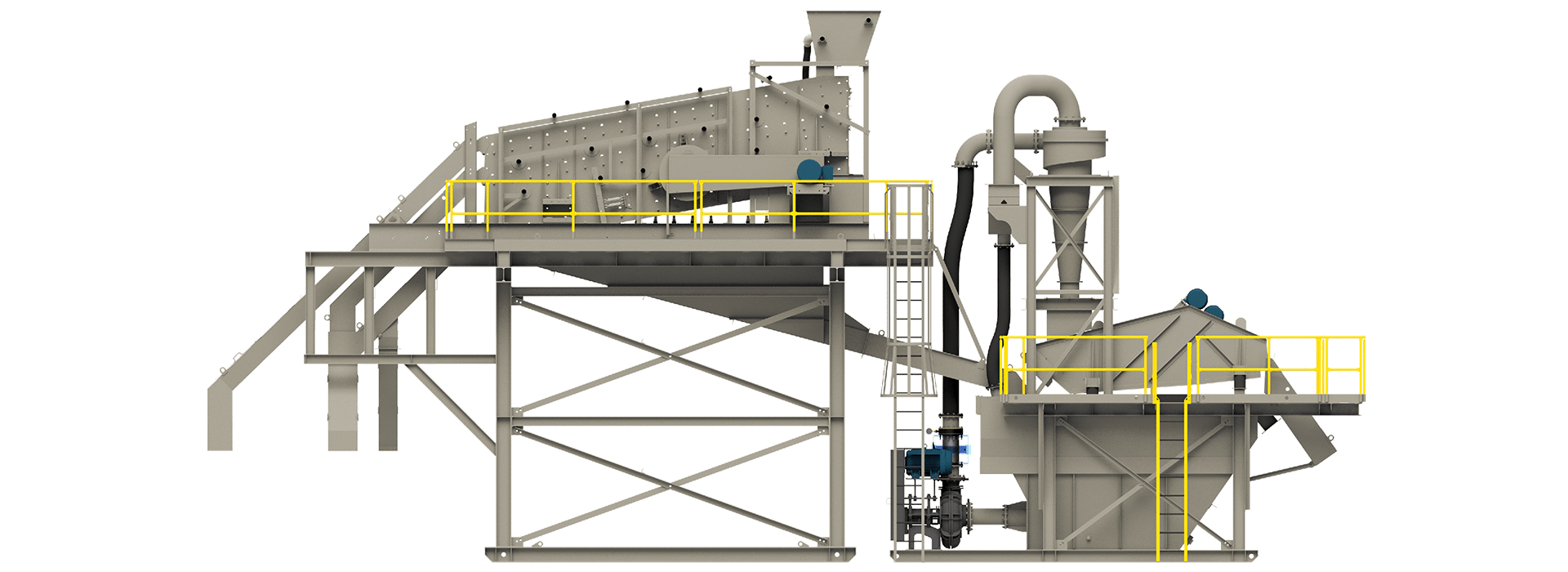

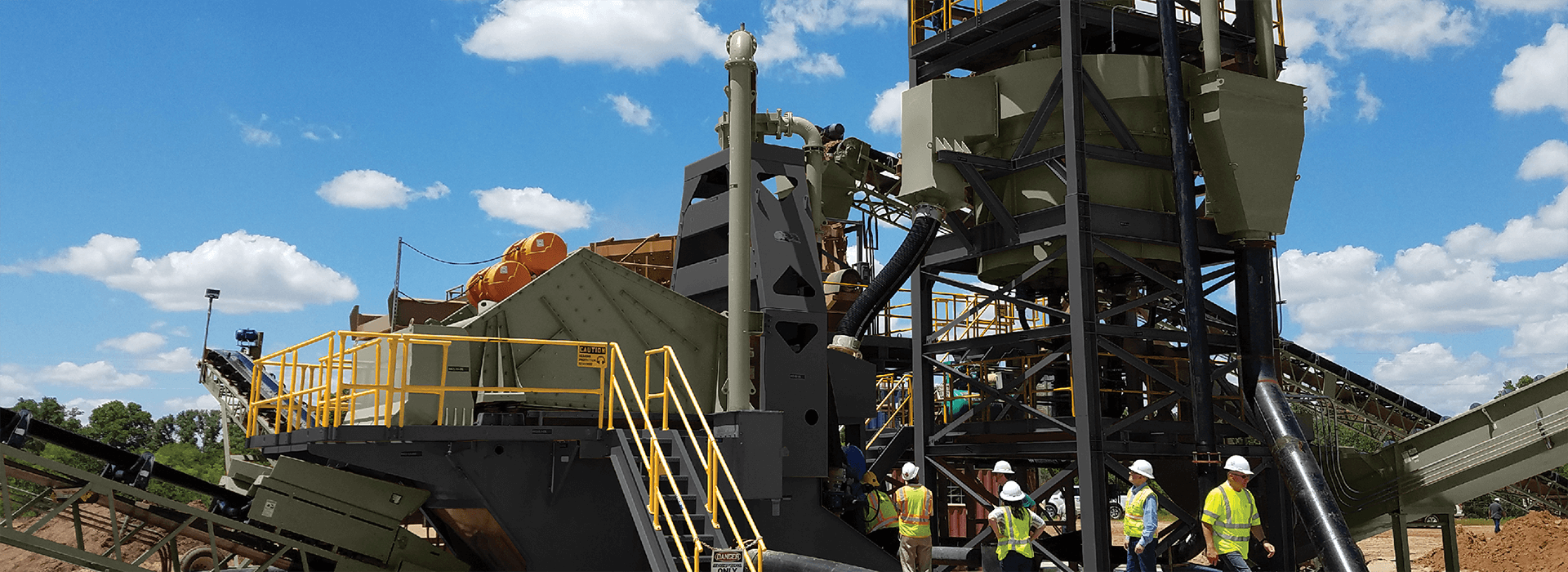

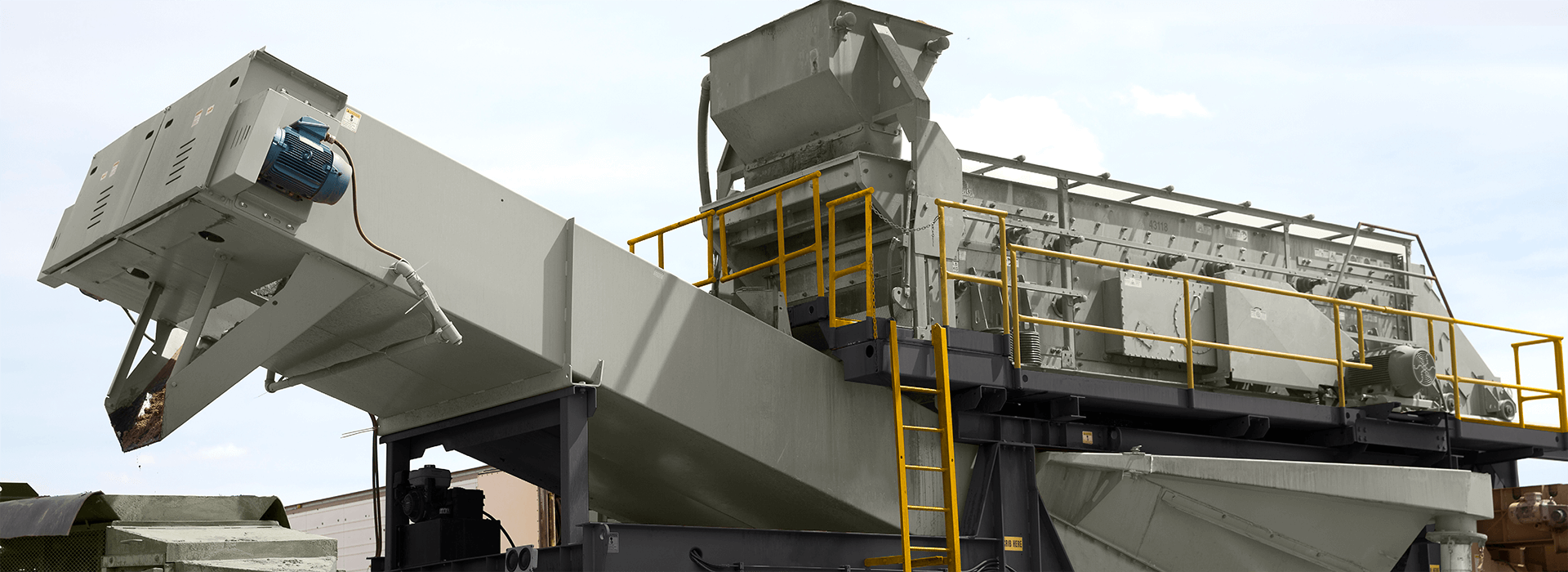

Modular Screening/Washing Plants - Шигшиж угаах үйлдвэр

• Variety of plant components including

conventional screens, dewatering screens,

cyclones, slurry pumps

• Skid-mounted, semi-portable and portable

configurations available

• Ideal for aggregate producers who require a

single plant to rinse and size material

Modular Sand Classifying Plants

• Applications can include frac sand, foundry

sand, glass sand, golf course sand, fines

recovery

•Plants can include dewatering screens,

cyclones, slurry pumps

•These plants are designed to dewater and fine-

tune sand products

Portable Screening/Washing Plants

• Plant components can include: screens, fine

material washers, blademills

• Portable configuration allows producers to

easily move plant for added convenience

• Variety of optional features for increased

maintenance, larger stockpiles and flexibility

DEWATERING EQUIPMENT - Хатаах тоног төхөөрөмж

Dewatering Screens

• Dewater sand products to a level typically not

possible with fine material washers

• Available in sizes ranging from 2'x 7 to 8'x 16

with processing rates up to 400 STPH

• Bolt-in UHMW pan side liners protect pan sides

from premature wear

Fine Material Washers

• The lowhorsepower requirement reduces

operating costs while increasing throughput

• Features standard, high-efficiency reducers

and bearings

• Adjustable overflow weir boards and collecting

flume allow control of the overflow slurry

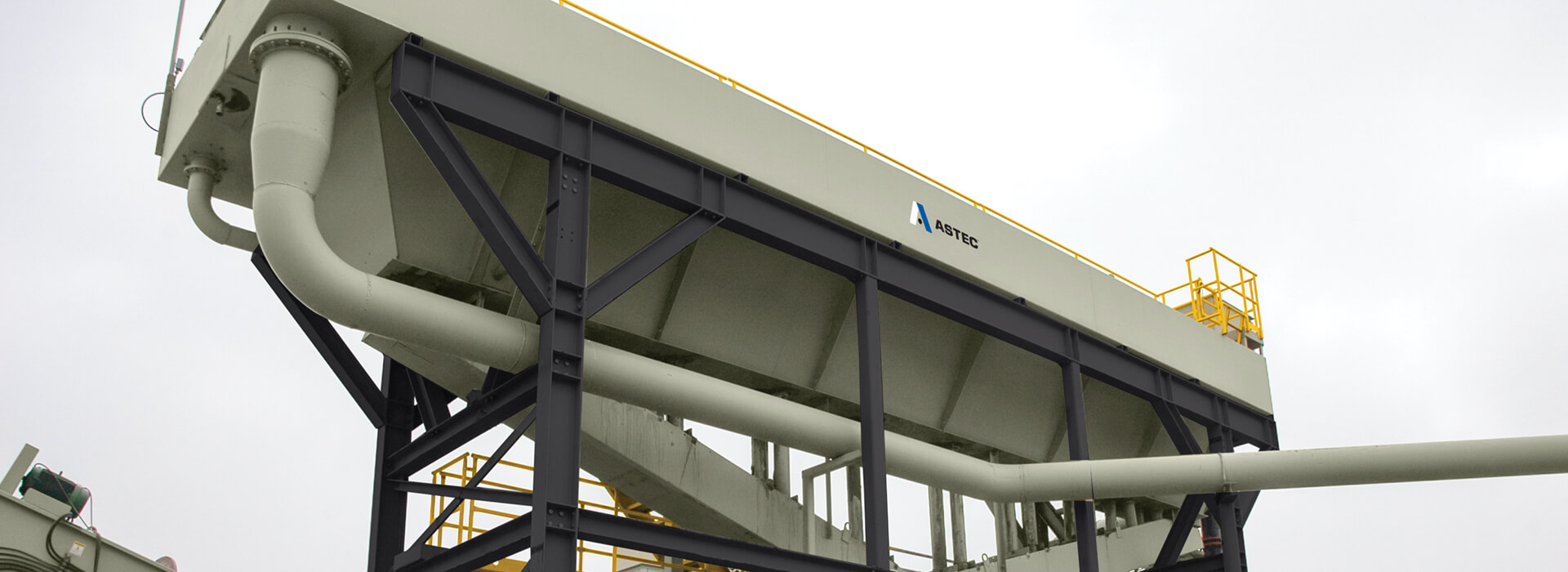

WATER CLARIFICATION - Ус цэвэршүүлэгч

Water Clarification Systems

• Allows producers to reuse up to 95% of their

water

• Features standard wastewater pit and pumps

• Utilizes a static vertical settling tank